I encourage everyone to take the time to study this page, as well as study the links provided through-out this article and website to further familiarize yourself with the SKS Carbine; more importantly, the SKS trigger group.

I encourage everyone to take the time to study this page, as well as study the

links provided through-out this article and website to further familiarize

yourself with the SKS Carbine; more importantly, the SKS trigger group.

![]()

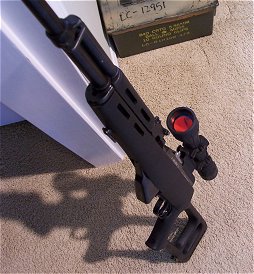

The SKS Carbine is an ever-increasingly popular firearm. Without a doubt nearly

every gun owner owns one, or has a friend who does. With the flood of

Yugoslavian SKS's on the market today, they are increasingly easier to get as

well. Almost every gun show, gun shop, or sporting goods store will have several

on display ranging from $79 for a fixer upper, to several hundred dollars for

the creme of the crop or the utmost of obscurity.

I personally spent many years hearing all my friends talk about they new SKS's

and how wonderful they are to shoot. I was finally bitten by the SKS bug in

2004, when I purchased my first (and by no means last) SKS. It didn't take long

for me to realize 4 boxes of ammo weren't going to last long...

As I am with all my investments, I take the time to research EVERYTIHNG

before I make a purchase. The same was true with the purchase of my first SKS. I

happened to find a wonderful forum called "Survivor's

SKS Boards" where I chatted with many well-informed SKS and mil-surp

enthusiasts. I now frequent the board as often as possible. I encourage everyone

who would read this page, to check out the board as well.

Through Survivor's SKS Boards, I was also introduced to another wonderful site,

SurplusRifle.com. Here you can find

tips and advice on collecting and maintaining a plethora or surplus firearms.

There are also detailed video clips and technical articles to be downloaded on a

multitude of surplus firearms.

![]()

Now that my introduction is out of the way, I would like to share some vital

information I think every SKS owner should be aware of.

Safety concerns with the SKS Carbine

| First is the possibility of a "slamfire," or worse the ignition of a round out of battery. | |

| The second being accidental discharge due to poor hammer/sear engagement. |

A "slamfire" is essentially an unintentional and uncontrollable discharge of

more than one round. It may be 2 of 3 rounds being fired instantaneously, or the

complete emptying of the magazine. It is usually caused by a seized firing

pin--due to debris, powder residue, cosmoline, or a host of other substances. It

can also be caused by using commercial ammunition with soft primers. This is

dangerous because it can happen unexpectedly and without warning. Yourself or

others could be harmed, or worse.

The SKS Carbine features a "free-Floating" firing pin which means it has no

spring to return and hold the pin rear-ward in the bolt. Since the firing pin

can freely "rattle" inside the bolt body, extra care must be taken to ensure the

firing pin channel remains clean. If the firing pin becomes stuck in a protruded

manner, and bolt is closed, the pin will strike the primer and ignite the round.

It is also possible that the first round will not be ignited until the trigger

is pulled, which will then jam the firing pin forward to the protruded postition,

triggering the involuntary ingition of some or all remaining rounds.

Since the SKS Carbine is a semi-automatic firearm, it will reload instantly

after the first round is fired. If the firing pin remains stuck in the forward

position, primers will continue to be struck involuntarily (without using the

trigger) until all remaining live rounds are fired. It is easy to see why this

is an unsafe condition.

The easiest way to remedy this problem is to assure your bolt is clean of any

and all residue. This can be done by many methods. Complete dis-assembly,

inspection, and cleaning is my preferred method.

It is my recommendation that the bolt be completely disassembled and the firing

pin channel be cleaned thoroughly (I find myself using pipe cleaners and

non-chlorinated brake cleaner). Soaking the bolt assembly is not sufficient

enough to clean out hardened, sticky cosmoline and other foreign debris. I also

discourage oiling the pin, as oils will only attract dirt and other residues

eventually seizing the pin (and that is what you're trying to avoid!!!).

For a detailed technical artical on how to dis-assemble your bolt, visit

Surplusrifle.com's article on

Bolt

Disassembly/Reassembly

A few side notes:

| Though firing pin orientation doesn't typically matter, in some Chinese variants the firing pin can be replaced upside-down in the bolt body, jamming it in the protruded postition. It might not be a bad idea to mark your firing pin's orientation with the body before your remove in from the bolt. | |

| Ben Murray makes a retro-fit kit that replaces your firing pin, with a new pin and spring. This will virtually elimitate the possibilitly of a "slamfire" all-together. For more info check out Ben Murray's website. |

This section will discuss the trigger group, with emphasis on the hammer and

sear.

There are 3 types of Hammer/Sear Engagement. They are:

| Negative Engagement - As the trigger is slowly pulled, the hammer moves forward slowly before breaking and contacting the firing pin. | |

| Neutral Engagement - As the trigger is slowly pulled, the hammer remains neutral and does not move before breaking and contacting the firing pin. | |

| Positive Engagement - As the trigger is slowly pulled, the hammer moves rearward slowly before breaking and contacting the firing pin. |

Of the three types of hammer/sear engagement, the positive type is the safest

and most desirable.

To check your SKS, pull your bolt back to cock the hammer, then remove your

receiver cover and recoil spring. Take care not to let the recoil spring shoot

across the room! You can now look down to see your hammer. Slowly squeeze the

trigger while watching the movement of the hammer. You may have to repeat

several times, as the movement can and will be minimal. (Keep your fingers

clear).

Why is hammer/sear engagement so important?

The safety mechanism on the SKS simply acts as "doorstop" to the trigger. It

does not disconnect the sear, or cease function of the hammer. Instead, it

simply keeps the trigger from moving rearword. If the rifle is cocked and

loaded, and is knocked, dropped, bumped, or the likewise the sear can still move

and the hammer can still drop. This is especially the case with a negative

hammer/sear engagement.

The best way to describe how this could happen is to use an analogy.

Let's say your car is dangling on the edge of a cliff, ready to fall hundreds of

feet to the bottom of a canyon. (This is the hammer in the cocked position.)

| If a bird lands on the hood of your car, which is over the edge of the cliff, your car will teater and fall into the canyon. (This is negative engagement as your SKS is accidently bumped) | |

| If you remain motionless in your car, as it teaters on the edge, you will most likely just remain there staring out the windsheild at your possible demise. (This is neutral engagement) | |

| If a tow-truck happens by and hooks up to the rear bumper of your car, pulling you away from the edge of the cliff, you will be saved from catastrophe. (This is positive sear engagement) |

But that doesn't make sense! How does it work?

When the hammer is in the cocked (rearward) position, it's edge is resting on

the sear. If you have a negative hammer/sear engagement, the sear actually

slopes downward toward the edge where the hammer releases. If the SKS is jarred

or bumped, the hammer can, under the tension of the hammer spring, slip down

that slope to the end of the sear and release firing the chambered round!

How do you correct this?

Positive hammer/sear engagement! If the sear slopes in the opposite direction as

it does in a negative engagement situation, if the sks is bumped or jarred the

hammer is forced away from the face of the sear and the hammer cannot possibly

be released!

My recommendation is: If you have a negative or even a neutral hammer/sear

engagement, GET IT FIXED!!!

I will cover a do-it-yourself method further down in this article.

In the mean time take extreme caution while handling. Take special care not to

bump or jar the firearm, as this could accidently set the hammer free.

Addressing the SKS Trigger

The SKS Carbine trigger, in general, is made to have a lot of trigger creep. If

your SKS is like most, there is some slack in the trigger. Once you get past the

slack, the second stage of the trigger is fairly rough and heavy. In most cases

the "creep" experienced in the second stage is quite lengthy.

What is the reason for this long pull 2-stage trigger? It is most likely a

safety concern. It is not uncommon to have new military recruits that have

little or no firearms experience. It is safer to give them a weapon with a long

trigger pull with a lot of slack over one with a "hair-trigger." There is a

lesser chance of accidental discarge by a jumpy cadet in a stressful situation.

This becomes especially critical when the user is running/jumping/diving around

in the mud, concentrating on everything else but his weapon. The extra creep

helps to assure the SKS only fires when the user means for it to fire.

The creep also acts as a cushion for poor hammer/sear engagement. In most cases

this large cushion of creep will help keep the hammer from releasing if bumped

or jarred no matter how poor your hammer/sear engagement is. I still recommend

you remedy neutral and/or negative engagement as it is still possible for the

hammer to accidently release.

My first SKS had negative hammer/sear engagement. As a test, I cocked the hammer

and bumped the unloaded firearm firmly on the ground 3-4 times. "CLICK!" the

hammer struck. The test was repeated with the same results. Imagine if the

firearm were loaded. A bump against a tree, accidently dropping it, tripping on

a root...all of these situations could be potentially lethal with the unsafe

firearm.

The SKS trigger is fairly complex in design, so If you don't feel comfortable

taking it apart or making any modifications then please don't! If you would like

to reduce the creep in your trigger, smooth out much of the roughness, lighten

your pull, and remedy your hammer/ sear engagement problems, visit

Kivaari's Little

Armory for an SKS Target/Match Safety Trigger Job. He comes highly

recommended, has a quick turn around, and will leave you in awe. You will shoot

better, and more happily!

If you would like to learn a little more about how the trigger works, and

possibly make your trigger function a little better on your own, please read on!

![]()

*NOTE: I am not a gunsmith, nor do I pretend to be one. This article merely represents my own experiences and understandings of the SKS Trigger Group. Any modification to any firearm may result in an unsafe condition. If you choose to modify your firearm you are taking inherent risks. Any injuries, damages, or the likewise will be the sole responsibilty of you, the modifier.The following is information I gathered via the internet and my own personal experiences with SKS trigger groups, and comes with no guarantee expressed or implied. If you proceed with any modification seen here, you are taking 100% liability for your actions! These steps require modifications to SKS specific parts. I recommend you make these modifications to spare parts so you do not accidently ruin your originals.

![]()

If you do not feel 100% confident with a modification you plan to attempt to

ANY firearm simply do no proceed. Firearms are not toys to tinker around

with. Your safety and the safety of others is in jeopardy when using a firearm

modified in an unsafe manner. Above all, make sure your firearm is UNLOADED

and NEVER USE LIVE AMMO to test the function of your firearm. NO

EXCEPTIONS!!!

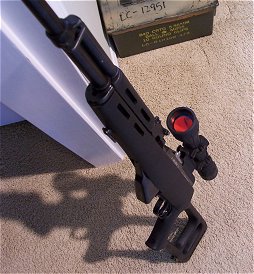

Here is a parts reference for the SKS Trigger Group:

The SKS Carbine has been produced by several countries. Variations in quality

and finish of parts is somewhat apparent from country to country. One thing that

is almost universal between all SKS's is the rough and sometimes gritty feel of

the SKS trigger. Some carbines are worse than others, though almost all could

use some improvement.

One of the easiest things to modify is the replacement of the hammer and sear

springs. Wolff Gun Springs makes replacement springs in lighter weights which

will make your trigger easier to pull, and possibly feel a bit smoother.

SurplusRifle.com also has a step-by step article on how to replace these

springs.

For information, or parts, for this modification see the following links:

| Wolff Gun Springs For lighter weight Hammer & Sear Springs | |

| Lightening the SKS Trigger A great SurplusRifle.com Article |

A big problem accuracy shooters have with the SKS is the amount of creep

built in to the SKS Carbine Trigger. Though not all SKS's have such drastic

creep, most do...and all can be improved. Improvement in this area is simple, if

you take the time to understand how the SKS trigger functions.

Once again, I will send you to a website article on how to reduce your trigger's

pull. The gentleman (Fragger) who created this article is a regular on

Survivor's SKS Boards. He is very

knowledgable, and is an avid SKS owner/collector. I would also like to thank

Fragger, as the Trigger Parts Illustration seen above was borrowed from his SKS

Trigger Re-Work page. THANKS!!!

For instructions on reducing SKS Trigger Creep

| Trigger Re-Work by Fragger |

I would like to emphasize the importance of taking your time and continually

checking your work as you proceed with this modification. I recommend you make

the modifications to a spare sear in case too much metal is removed. Also, be

sure you leave SOME creep in the trigger for added safety. A hair-trigger

is not the safest condition with the SKS's Trigger design. Please don't get

over-zealous in modifying your trigger. Safety should always be your number one

concern!

As an addendum to this article, check to make sure your safety works properly.

Set your safety then attempt to pull the trigger. The trigger bar should not

contact the sear AT ALL! If the trigger bar does contact the sear, no

matter how slight, your may have rendered your safety inoperable, and you will

have to do some slight filing to the sear or trigger bar. Again, take your time

and continually check your progress.

If you plan on reducing trigger creep, polishing your sear/rails, and

installing lighter weight hammer and sear springs, you MUST also insure

you have a Positive engagement of the Hammer/Sear. As I mentioned before, the

substantial creep of the trigger acts as a safety cushion for poor hammer/sear

engagement. If you have removed the creep, you have also removed this safety

cushion, and therefore are putting yourself and others in higher risk with

accidental discharge.

This modification is sear intensive, so again I recommend you make the

modifications to a spare sear in case irreversable harm to the sear is done.

Your goal with this modification is to remove as little material as possible,

while at the same time improving hammer/sear engagement. You do NOT want

to remove much metal!

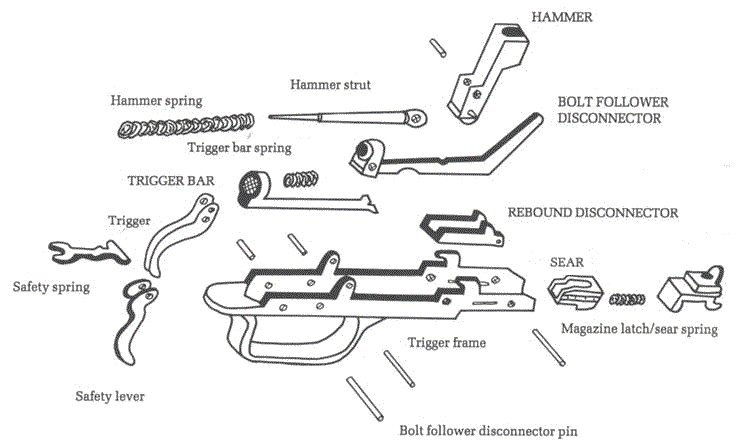

Here is a picture of an example sear after this modification.

Modifications were done with an extra fine, half round diamond file and 600 grit

wet/dry sandpaper.

Notice the incredibly small dimple in material highlighted within the red box.

This divot, however slight, gives a positive hammer/sear engagement and will

keep the hammer from accidently releasing if bumped. When bumped, the hammer

(under tension of the hammer spring) will follow the path of least resistance or

migrate to the bottom of this dimple, away from the edge of the sear (no

accidental release!).

Please bare with me, as I will be using PaintShop "artist's renderings" of the trigger group for this section.

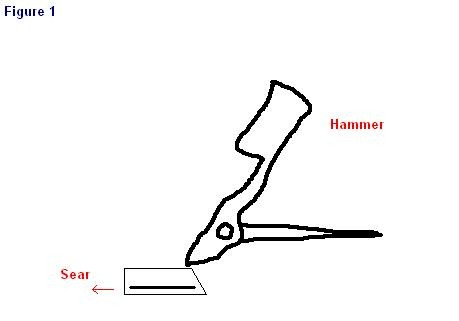

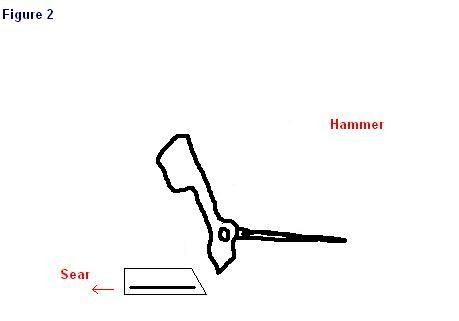

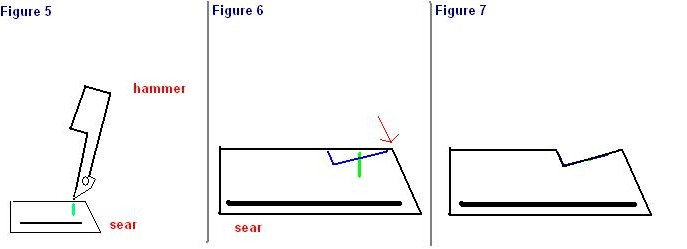

Image 1 shows the the relationship of the hammer to the sear. The lower edge of

the hammer rides on the top of the sear. As the sear is pushed forward, the

hammer gets closer to the edge of the sear. Figure 2 shows what has occured once

the sear has moved out of the way.When the hammer has reached the edge, the sear

no longer acts as a stop, and the hammer is released and flies forward.

So what does it require to create a positive hammer/sear engagement?

Think of the hammer at a teeter-totter. The top end of the hammer (that strikes

the firing pin) is one end of the teeter-totter. The lower end (where the hammer

rides on the sear) is the other end of the teeter-totter. The "pin" the hammer

rotates on is the balance point. Push up on one end, the other end goes down.

Push down on one end, the other goes up. This is the mode of thinking you must

be in at this point.

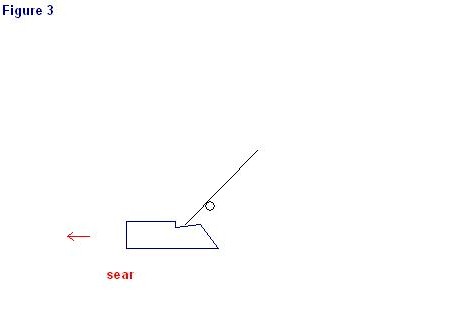

Figure 3 shows a modified sear. Notice the notch taken from the top of the sear.

The hammer has been replaced with a "teeter-totter" to help display how this

notch effects hammer/sear engagement. I'm going to ask you to use your

imagination here. Picture the sear moving forward as the arrow shows. As the

sear moves forward, the teeter-totter is forced to climb up the "ramp" created

on the top of the sear. As the lower portion of the teeter-totter is forced up

the ramp, the opposite end of the teeter-totter is going down. This is

positive hammer/sear engagement! As the sear is pushed forward, the hammer

moves rearward before breaking free! If the firearm were knocked or jarred in

this situation, the hammer (being under high spring pressure) would take the

path of least resistance. In this case, that would be down the ramp, and away

from the end of the sear! This is why positive engagement is so important. If

the firearm is knock or jarred, the hammer will not be knocked closer to the

edge of the sear, but rather away from the edge! This ensures the hammer will

not accidently release!

I will also show you an example of negative hammer/sear engagement to help you

further understand this concept.

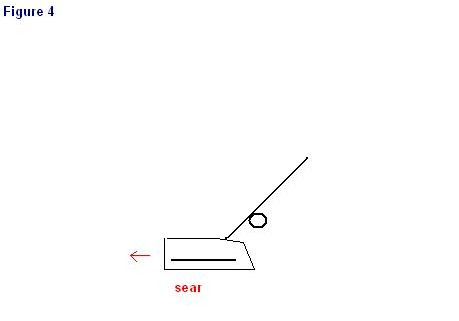

Figure 4 shows negative hammer/sear engagement. Notice that as the sear would

move forward, the lower portion of the "teeter-totter" will be moving down a

ramp on top of the sear. Moving down the ramp lowers the bottom portion of the

teeter-totter, so conversley the other end of the teeter totter is going UP.

This is what you DO NOT want! In this situation, the hammer would

creep forward as the trigger is slowly pulled. This also means that if the

hammer is cocked, and the firearm is knocked or jarred, the hammer would again

take the path of least resistance. In this case, downhill, and would creep

further toward the edge of the sear and possibly even release causing an

unwanted accidental discharge!

How do you rememdy poor hammer/sear engagement?

| First you need to cock the hammer and take note of where on the top of the sear the hammer naturally rests. (Figure 5) | |

| Next, you will need to remove the sear from the trigger group. | |

| Using an ULTRA FINE Jeweler's type file, create a notch on the top of the sear similar to that seem in figure 7--The notch is exaggerated--you do NOT need to remove this much material. It does not require much metal removal to reach your goal. Remember the example sear from above! A deep notch creates a heavier trigger pull due to the hammer being pulled back (against spring tension) more than necessary as the sear is released. | |

| The notch needs to start just forward of where the hammer naturally rests on the sear when cocked. (figure 6) Notice the green mark is where the hammer naturally rests, the blue portion shows where your notch should be. Take extreme caution not to remove any metal from the edge of the sear where the hammer is released (red arrow). Removing any metal here will cause adverse effects (Negative Sear Engagement!!!) As with any modifications here, remove small amounts at a time and Continually check your progress! | |

| Once the filing is complete, polish away the filing marks with fine sand paper or other methods. The smoother the top of the sear is, the smoother your trigger will feel when everything is reassembled. Again, take care not to get too close to the edge of the sear. You want the end to remain even and crisp. | |

| That's it! Take caution when re-assembling everything. Make sure you don't marr any of your freshly polished surfaces. Coat the sear grooves, sear, hammer, and frame rails with a light coat of oil or gun grease. | |

| The last thing you need to do is ensure all your hard work actually did improve your firearm. Repeatedly test by cycling your bolt and pulling the trigger. Make sure the hammer is being cocked and held securely in place by the sear. Make sure the trigger is releasing the hammer, and nothing else. Cock the hammer, and with the safety on, repeatedly (15 times) firmly place the firearm's butt on the ground. Slap it with your palm. Bump it against a wall. Drop it on the floor from a few inches. Make sure the hammer has not released...after 15 knocks/jarrs/and jolts release the safety and pull the trigger. If you her that signature click of the hammer, you did it right! Sit back, and suck down a cold one for all your efforts! Your SKS is now safer and the trigger is much more enjoyable! |

![]()

SKS page 26 for more info on the SKS Cut-Aways !!

This page is published with written permission of Bscman

YooperJ

Started in 1999

by [Yooper John's]. All rights reserved.

Revised:

04 Mar 2016 12:54:28 -0600 .